4 Ways AI is Transforming the Manufacturing Industry

Can AI revolutionize the manufacturing industry? It’s already happening.

In Germany, 13.3% of companies currently use AI, with 9.2% planning to adopt it soon. Additionally, 36.7% of businesses are exploring potential AI applications.

So why can’t we go down that road?

AI is an advanced technology that enables machines to learn from data. It adapts to new situations and performs tasks that traditionally require human intelligence.

Here, we have discussed 4 real-world examples of how AI transforms the manufacturing industry and relevant case studies for better understanding.

1. Predictive Maintenance

Predictive maintenance employs data analytics, machine learning, and IoT sensors to foresee equipment failures by analyzing historical and real-time data. By detecting patterns and irregularities, maintenance teams can schedule repairs preemptively.

Benefits of Predictive Maintenance

- Proactive maintenance prevents costly interruptions.

- Optimization reduces repair expenses.

- Advanced identification enhances equipment reliability.

How is Siemens Using Predictive Maintenance

Siemens has led the adoption of AI technologies. They aimed to transform its manufacturing operations and enhance productivity.

One of their most notable AI applications is predictive maintenance. It aims to minimize downtime, optimize maintenance practices, and improve operational efficiency. With AI-powered predictive maintenance, manufacturers can anticipate equipment failures before they occur.

Let’s see how Siemens Uses Predictive Maintenance

2. Generative Design

Generative design revolutionizes product design and development through AI. This generates a range of design options based on specified parameters. It enables manufacturers to explore innovative design solutions that might not have been possible with traditional methods.

It also uses AI to modify manufacturing by autonomously generating alternate designs. Connecting industrial IoT, machine learning, deep learning, computer vision, and natural language processing with generative design drives manufacturing innovation.

Advantages of Generative Design

- Faster time-to-market

- Improved product performance

- Enhanced efficiency

BMW Using Generative Design to Stay Atop

BMW, a top global automotive firm, heavily invests in tech to stay ahead of its competition. Taking up AI, the German automaker incorporates it across operations, spanning design, manufacturing, and more.

We can see here how they used generative design to prototype and optimize new products rapidly,

3. Robotics and Automation

AI-driven robotics and automation improve efficiency and precision in manufacturing. One example is autonomous mobile and collaborative robots, which showcase AI's role in the industry.

These robots align with Industry 4.0 and smart manufacturing principles. It uses advanced technologies like industrial IoT, machine learning, deep learning, computer vision, and natural language processing.

Benefits of Intelligent Automation

- Improved safety by minimizing human intervention in hazardous tasks.

- Higher throughput through streamlined workflows and automation of repetitive tasks.

- Greater flexibility to adapt quickly to changing production demands and market requirements.

Nike and their Intelligent Automation

Nike, a top player in sportswear, invests heavily in AI and emerging tech to transform products, customer experience, supply chain, and IT operations.

We can see below how Nike uses AI in manufacturing

4. Quality Control

Manufacturers employ computer vision and AI for automated visual inspection, enhancing quality control by analyzing images or videos to detect defects efficiently.

AI-based quality control systems can detect even the slightest deviations from specifications, ensuring that only flawless products reach the market.

Other areas where AI is making an impact in manufacturing include:

- Optimizing production scheduling

- Maximizing yield

- Enabling predictive quality control

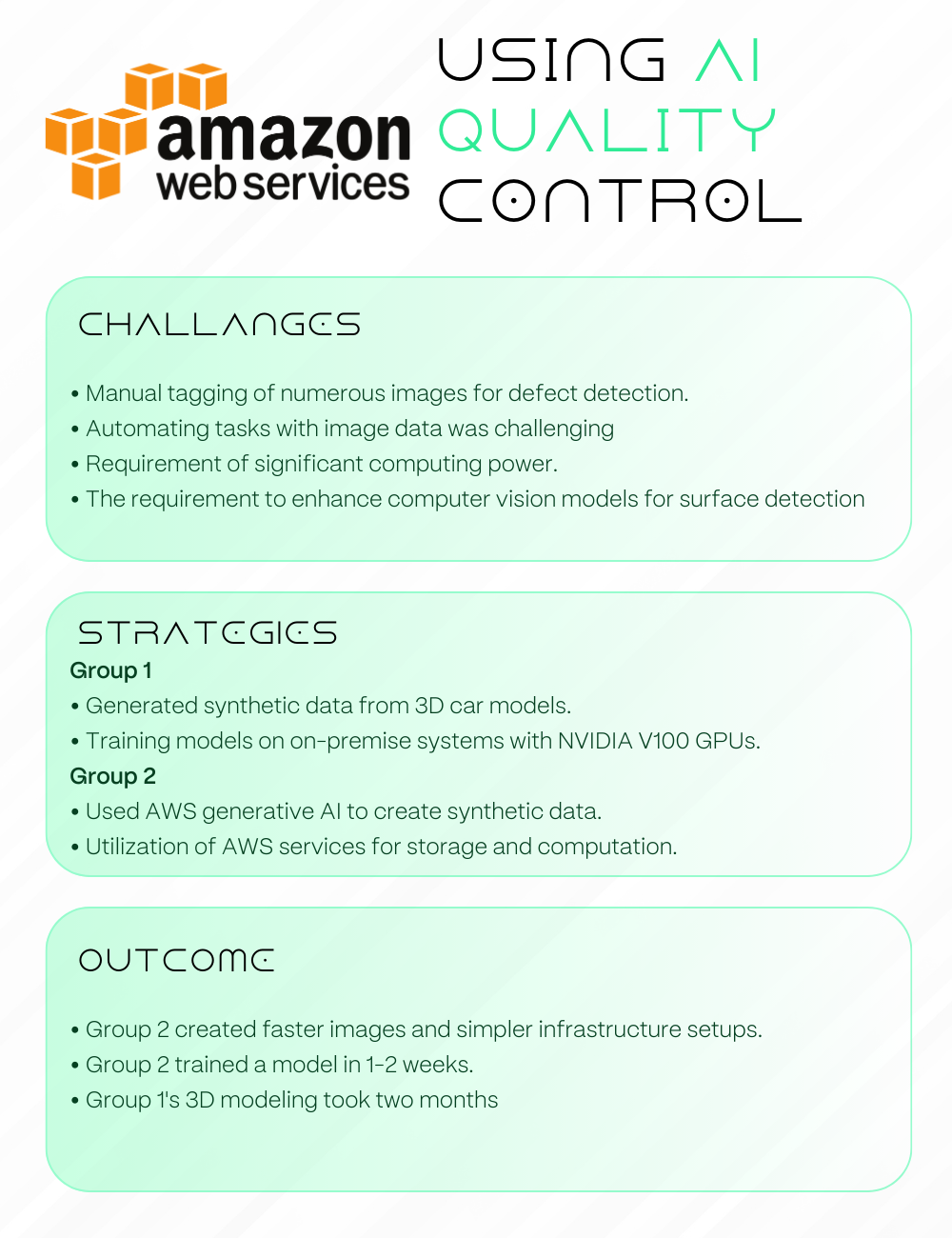

Amazon Web Services Using AI-powered Quality Control

Amazon Web Services offers a broad range of cloud-based products globally.

It covers computing, storage, databases, analytics, networking, mobile, developer tools, management tools, IoT, security, and enterprise applications. These services are instantly available with pay-as-you-go pricing.

AI, combined with industrial IoT and machine learning, enables real-time monitoring and automatic adjustment of manufacturing processes. This improves product quality and efficiency.

Let’s see how defect detection rates and efficiency gains are achieved with AI

Conclusion

AI is already making its place in the manufacturing industry with its ability to enhance productivity, efficiency, and innovation. A notable percentage of companies are actively utilizing AI, and many are exploring its potential. As seen with leading companies like Siemens and BMW, AI improves productivity, reduces costs, and enhances reliability.

The future of manufacturing is smart and AI-driven, offering exciting opportunities for growth and a competitive edge to those who successfully integrate AI technologies. It continues to reshape manufacturing's future in impactful ways.