Machine Learning in Manufacturing: Revolutionizing Quality Control and Automation

AI and machine learning power Industry 4.0, enhancing manufacturing efficiency and quality. The fourth industrial revolution is characterized by the integration of advanced manufacturing technologies, including Artificial Intelligence and Machine Learning.

It involves intelligent factories with interconnected machines, emphasizing automation, data exchange, and self-optimization. ML algorithms learn from data to predict equipment issues and enhance production outcomes. AI and Machine Learning are revolutionizing quality control and automation in manufacturing, improving efficiency, reducing costs, and enhancing product quality.

This blog will discuss how machine learning impacts quality control and manufacturing automation through real-life examples.

Using Machine Learning for Quality Control

Machine learning improves quality control by analyzing data from various sensors and cameras to detect defects and ensure product quality. This enhances accuracy, reduces human error, and improves efficiency in inspection processes. ML techniques like computer vision enable machines to inspect products, ensuring they meet specifications.

Benefits of Using Machine Learning for Quality Control

- AI-driven quality control reduces flaws, enhancing reputation and customer satisfaction.

- Early defect detection lowers rework and scrap costs.

- Streamlined inspections improve production speed and resource utilization.

Real-Life Examples of ML in Quality Control

Let’s discuss some real-life examples of Machine learning enhancing quality:

Facial Recognition

Facial recognition, an obvious application of machine learning, has multiple uses. From name suggestions on mobile photos to identity verification, this technology analyzes facial contours. In healthcare, it aids in genetic disease detection and medication tracking. As more data is analyzed, applications expand, improving accuracy.

Product Recommendations

Machine learning influences retail by grouping consumers based on buying habits and demographics. Targeted marketing uses ML to predict preferences and make suggestions. While some recommendations are apparent, ML uncovers hidden relationships in data, predicting preferences before consumers realize them. These instances provide valuable learning opportunities.

Email Automation and Spam Filtering

Behind the scenes, machine learning drives email functionality. Email automation streamlines communication, while spam filtering adapts to undesirable content patterns. User feedback on misidentified spam improves accuracy. ML enhances our digital communication and streamlining experiences.

Machine Learning in Manufacturing Automation

Machine learning applications in automation enhance efficiency and accuracy. ML algorithms can analyze patterns, make predictions, and optimize processes. ML techniques like computer vision enable automated inspections, defect detection, and process optimization. It also improves productivity and resource utilization. ML models learn from data, adapt over time, and improve manufacturing outcomes.

Benefits of Machine Learning in Manufacturing Automation

- Streamlines processes and reduces costs.

- ML models learn and improve over time.

- Optimized processes and reduced manual labor.

- Forecasts equipment issues.

- Maximizes output and minimizes waste.

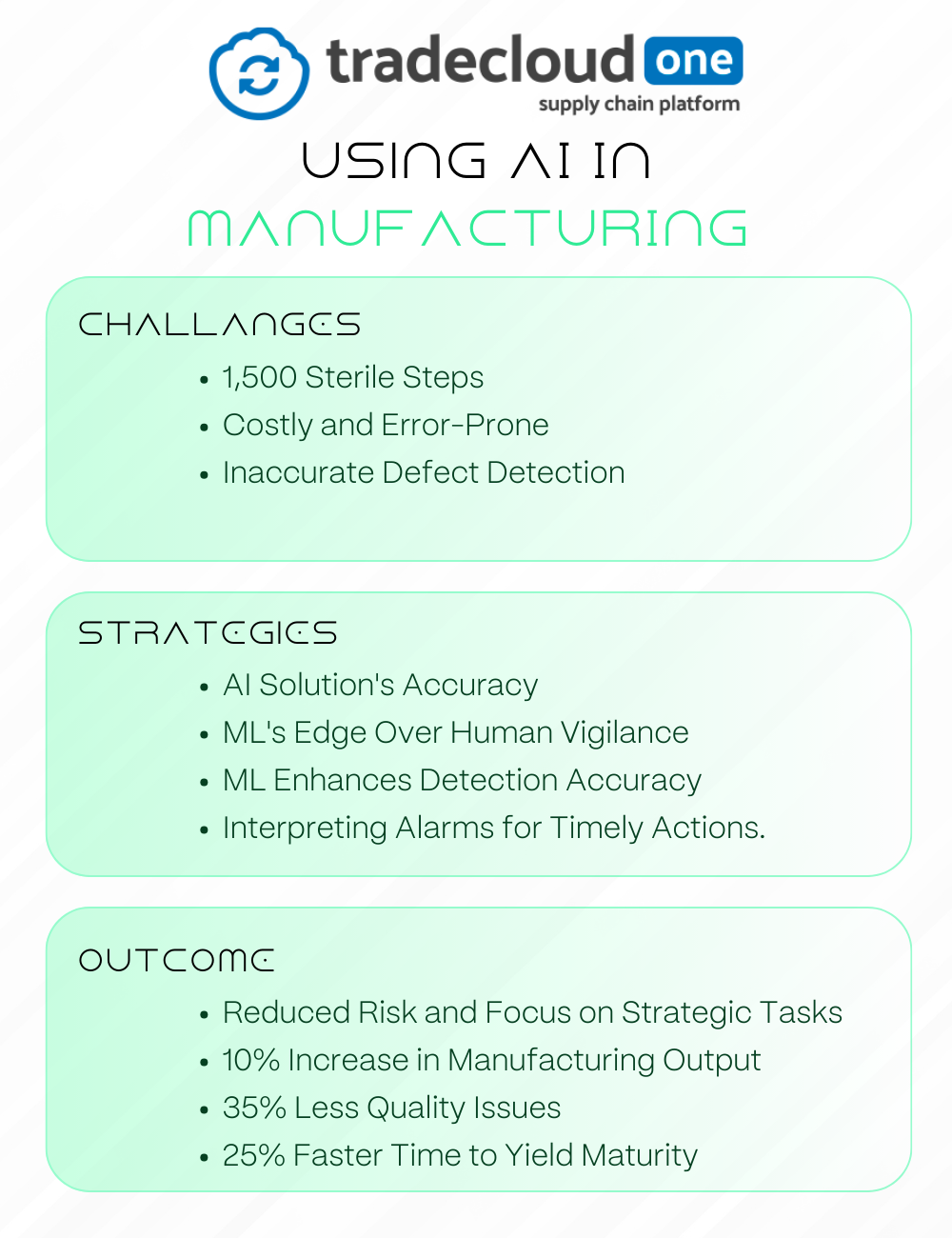

How Tradecloud One Uses Machine Learning in Manufacturing Automation

Tradecloud One is a supply chain platform that empowers fast-growing manufacturing companies to optimize their global supply chain. It offers real-time collaboration, automated processes, and accurate forecasting, reducing waste and enhancing growth. Here is how they used AI to transform their manufacturing:

Challenges of Using ML and AI in Manufacturing

ML enhances manufacturing with defect detection, improving speed and efficiency, but it comes with challenges. Here is a list of things one needs to remember:

- Data Quality: High-quality, diverse data is vital for accurate predictions. Ethical considerations focus on data privacy and addressing algorithmic bias. Adapting the workforce through upskilling programs ensures a smooth transition to ML-driven automation.

- Workforce Adaptation: Upskilling programs facilitate worker transition to ML-driven automation, enhancing their skills and adaptability.

- Integration and Compatibility: Ensuring seamless integration with existing systems is crucial for successful ML implementation and optimal performance.

- ML Understanding: Improving worker skills in ML enhances adaptability and job satisfaction, improving overall efficiency.

- Maximizing ROI: Investing in machine learning technologies upfront can lead to cost savings, offering businesses a valuable return on investment.

- Business Potential: ML automation boosts productivity output quality, leading to increased profitability and positive business outcomes.

Future Trends and Opportunities

Emerging technologies like digital twins and edge computing enhance ML applications. Digital twins create virtual replicas, improving simulation and testing. It brings processing power closer to data sources, enhancing real-time insights. These advancements improve ML accuracy and enable innovative solutions. Continued innovation and adoption of ML technologies are crucial for unlocking new business opportunities.

ML-driven insights and automation improve efficiency, leading to new revenue streams and competitive advantages. Incorporating innovation ensures long-term success and adaptability in a dynamic market.

Final Word

AI and machine learning are at the heart of the manufacturing revolution, improving quality control and reducing costs. As Industry 4.0 unfolds, these technologies will be vital in creating quick and responsive manufacturing systems.

The impact of AI and ML in manufacturing is undeniable, and further integration will shape a dynamic and prosperous era for the industry. They are the key drivers of this revolution, and businesses must embrace these technologies to stay ahead.