8 Ways to Use AI in Logistics - Revolutionize Supply Chain Management

AI has helped businesses improve logistics costs by 15%, Inventory levels by 35%, and service levels by 65%. Logistics companies are estimated to generate $1.3-$2 trillion in economic value over the next 20 years. This shows the role of AI in revolutionizing supply chain management.

In this article, we will explore how AI is reshaping supply chain management and uncover the benefits and challenges it brings.

The Role of AI in Supply Chain Optimization

AI contributes to supply chain optimization by enhancing demand forecasting, route planning, inventory management, and last-mile delivery. It improves accuracy, speed, and customer satisfaction in the supply chain. AI optimizes shipping, inventory tracking, and demand forecasting in supply chains. It enhances warehouse management, worker safety, and transaction integrity.

Here are some benefits of using artificial intelligence for logistics:

- AI streamlines logistics processes, reduces costs, and improves productivity.

- Demand forecasting, predictive analytics, and powered AI improve planning accuracy and inventory optimization.

- AI-driven optimizations enhance the customer experience through timely deliveries and accurate order fulfillment.

- It provides data-driven insights, enabling swift and informed decisions.

- Its optimizations reduce labor costs fuel expenses, and minimize the impact of unforeseen events.

Top AI Use Cases in Logitsics

Here is a list of AI uses in supply chain management:

1. Predictive Analytics for Logistics

AI systems can significantly improve demand forecasting and inventory management by analyzing historical data and patterns. This enables logistics providers to anticipate peak demands and optimize stock levels.

The predictive analytics market is booming. It reached $1.95 billion in 2022 and is projected to soar to $2.25 billion by 2028.

Predictive analytics also aids in route planning and capacity utilization, reducing transportation costs and improving delivery times.

The benefits of predictive analytics include:

- AI predicts market changes and enhances inventory management.

- Optimized routes reduce costs and improve delivery times.

- Data-driven insights enable better decision-making and strategic planning.

- Predictive analytics help businesses quickly adapt to market dynamics.

- AI-driven forecasts minimize stockouts and overstocking, reducing operational costs.

Optimizing Logistics

31% of supply chain managers use predictive and prescriptive analytics, which enhance operational efficiency. Predictive analytics is about more than just predicting demand. It can also revolutionize shipping routes and delivery times, enhancing logistics by optimizing routes and consolidating shipments.

2. Intelligent Transportation Systems

The global intelligent transportation system market size crossed USD 34 billion in 2022 and is projected to reach $65.33 billion by 2032, growing significantly. Intelligent transportation systems revolutionize transportation with wireless, electronic, and automated technologies. They integrate vehicles, users, and infrastructure for efficient trips, reduced congestion, and improved air quality. ITS technologies include precision docking, route guidance, and collision avoidance, enhancing transportation safety and efficiency and giving in-depth insight.

The benefits of gaining in-depth insight are mentioned below:

- AI insights aid strategic growth and expansion.

- Identify opportunities and market gaps for growth.

- Discover segments and markets for product diversification.

- Future-proof your business, staying ahead of transportation trends.

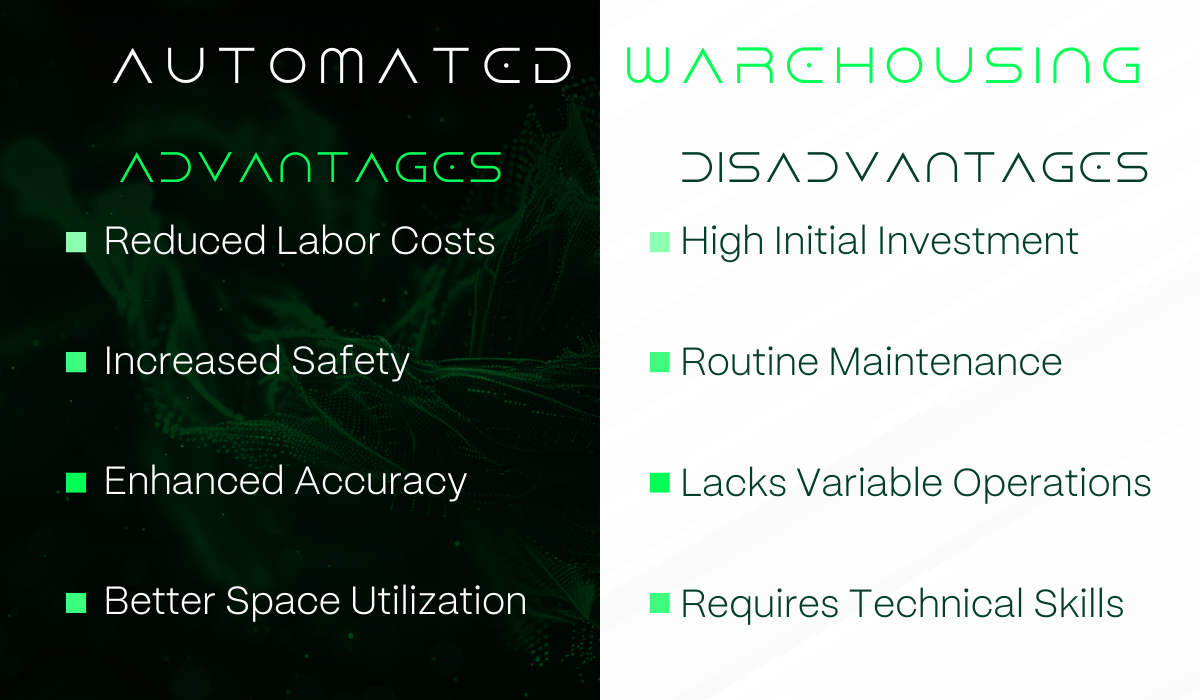

3. Automated Warehousing

AI-powered automation transforms warehousing operations. Automated guided vehicles (AGVs) and robotic arms efficiently handle inventory management, order picking, and packaging tasks. AI algorithms optimize inventory placement based on demand patterns, reducing picking times and enhancing warehouse utilization.

Computer vision systems accurately identify and sort products, improving picking accuracy and reducing human error. Automated warehousing improves overall efficiency, saves costs, and frees up staff for more strategic tasks.

4. AI-Powered Demand Forecasting

AI-driven demand forecasting enables businesses to anticipate market changes and adjust their strategies proactively. By analyzing historical data, customer behavior patterns, and external factors, AI systems can predict demand fluctuations and help businesses optimize their supply chain. This enhances inventory management, reduces excess stock, and ensures products are available when and where needed.

Use of AI in Logistics Demand Forecasting

Implementing AI in logistics operations requires careful planning. Here are some steps to successfully integrate AI into demand forecasting:

- Set Clear Objectives: Define success metrics and goals for AI-powered demand forecasting.

- Data Collection: Gather and integrate sales, market trends, and external factors.

- Model Selection: Choose AI models (regression, neural networks) based on complexity and needs.

- Continuous Learning: Regular updates ensure forecasting accuracy and adaptability.

- Data Preprocessing: Ensure data quality and relevance through cleaning and structuring.

- Train and Validate: Train with historical data validated with independent tests.

- Integrate and Monitor: Implement and closely watch AI performance, ensuring ongoing accuracy.

5. Machine Learning

Machine learning algorithms excel at recognizing patterns in data and improving decision-making processes. Logistics providers can identify inefficiencies, optimize pricing strategies, and enhance revenue management.

Machine learning models can predict market trends, identify potential disruptions, and suggest proactive solutions. This enhances the supply chain's responsiveness and adaptability, ensuring a steady flow of goods and efficient resource allocation.

Logistics providers leverage machine learning to optimize various processes:

- Predicting demand with data insights.

- Improving deliveries and costs.

- Streamlining stock levels.

- Maximizing revenue.

- Enhancing security.

7. AI Route Optimization

AI route optimization algorithms leverage real-time data to optimize delivery routes, reducing transportation costs and improving fuel efficiency. These algorithms consider traffic, weather, and delivery priorities to plan the most efficient routes.

AI-optimized routes enhance last-mile delivery, reduce environmental impact, and improve customer experience. Route optimization also ensures timely deliveries, enhances driver safety, and optimizes the utilization of delivery resources.

Importance of AI Route Optimization

Some of the essential takeaways of AI route optimization are listed below:

- Optimized routes reduce travel time, improving delivery speed and customer satisfaction.

- AI-driven route optimization ensures optimal utilization of fleet and driver resources, avoiding empty runs and improving operational efficiency.

- They help drivers navigate unexpected events and adverse conditions, improving safety and reducing traffic accidents.

- Reliable and timely deliveries at lower costs attract shippers and enhance market competitiveness.

A recent analysis predicts that 2030 the market for route optimization software will be worth $21.7 billion. This shows the rising need for effective delivery operations and the potential contribution of AI to this goal.

8. Autonomous Vehicles

Autonomous vehicles, including drones and self-driving trucks, are set to transform delivery and distribution models. These vehicles can navigate routes efficiently, reduce human error, and ensure just-in-time deliveries.

Autonomous vehicles improve road safety, enhance fleet management, and provide real-time updates on delivery status. They offer flexibility, optimize last-mile logistics, and redefine the traditional delivery landscape, improving overall distribution efficiency.

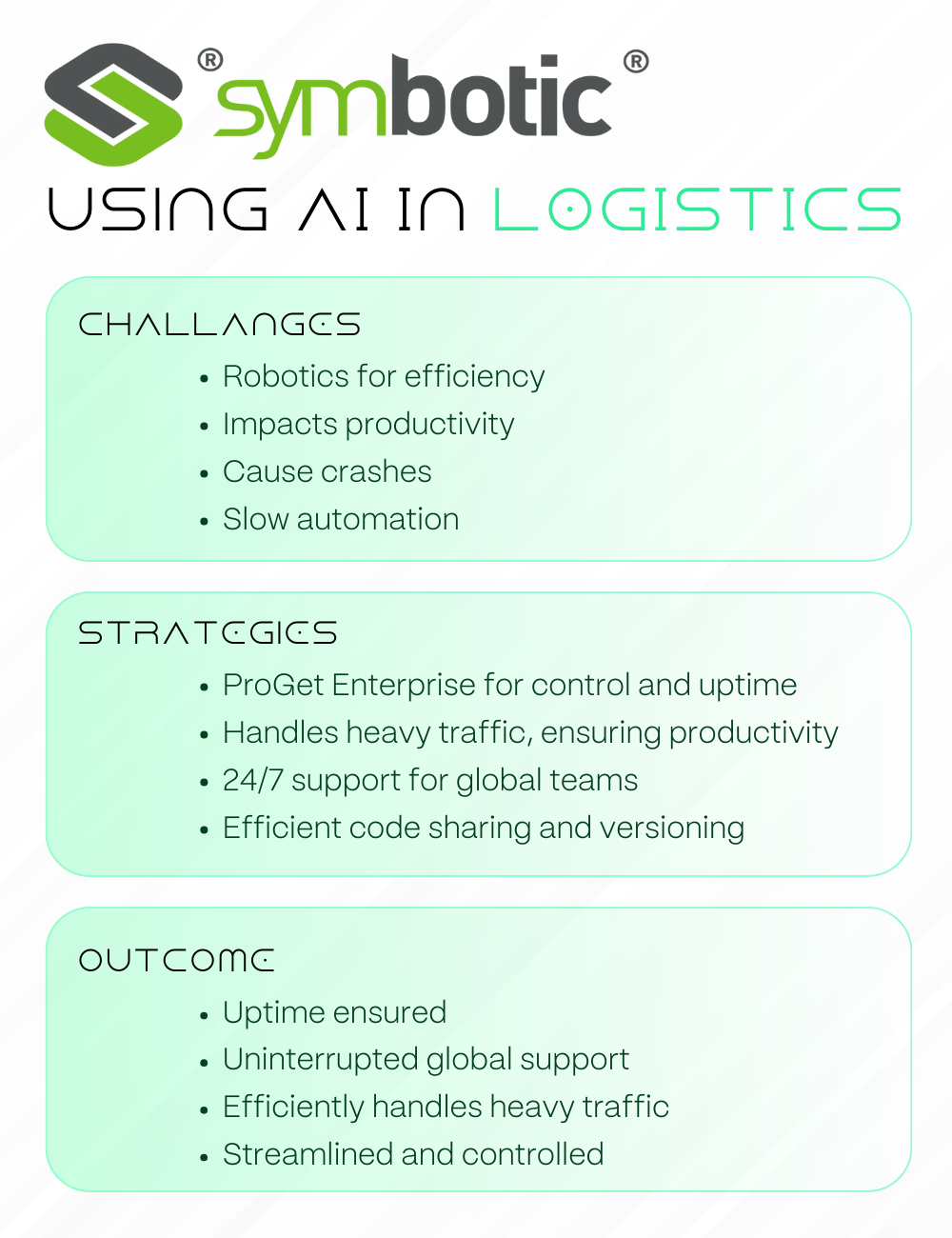

Symbotic Using AI in Logistics

Symbotic is a US-based robotics firm that revolutionizes warehouse automation with AI-powered software, enhancing efficiency for clients in America. Here is how Symbotic is using AI to improve their logistics:

Final Word

AI is transforming supply chain management, offering unprecedented opportunities for optimization. From predictive analytics to autonomous vehicles, AI technologies enhance efficiency, accuracy, and customer satisfaction. Logistics providers and retailers who embrace AI gain a competitive edge, improve their bottom line, and elevate the overall customer experience.

As AI continues to evolve, its combination with logistics operations will further drive digital transformation and reshape delivery models. It will ultimately revolutionize the way goods are transported and distributed worldwide.